Fieldhouse Engineering Ltd were contracted by the Science and Technologies Facilities Council to design the liquid nitrogen supply system for the National Satellite Testing Facility (NSTF).

The description of the site and requirements of the project are outlined below:

The NSTF is a large building (approximately 70 m x 50 m) housing testing facilities and clean rooms, intended to perform environmental testing on satellites ranging in size from 1 tonne to 7 tonnes.

The test facilities include a large thermal vacuum chamber (7.0 m internal diameter x 12 m long) that has thermal shrouds to heat and cool test items placed inside. The shroud panels can be cooled to 95 K using a cold nitrogen gas system and heated to 400K by heating the cold nitrogen gas using a heat exchanger.

Cooling for the nitrogen gas is provided by liquid nitrogen (LN2), and under worst-case conditions, the rate of consumption of LN2 is predicted to be around 2.5 tonnes per hour. The liquid nitrogen, stored in bulk storage tanks, needs to be transported to the point of use via a thermally insulated pipe to minimise evaporation and ensure the quantity of bubbles in the LN2 is less than 2%. The most thermally efficient solution is to use a super insulated vacuum line (SIVL).

After the liquid nitrogen has been used for cooling purposes, the now gaseous nitrogen has to be vented to atmosphere in a safe manner. An exhaust vent, or stack, is necessary to ensure the nitrogen gas does not accumulate around air intakes to the building or around locations where personnel might congregate.

In addition to the supply of LN2, a gaseous nitrogen (GN2) system is needed to supply clean, dry nitrogen to various locations inside the NSTF building. The most efficient way of providing the GN2 is by using boil-off gas from the bulk storage tanks. However, when demand is high it will be necessary to vaporise some of the LN2 in a vaporiser system.

The temperature of the GN2 needs to be between 15 and 35 °C, so additional heating of the boil-off gas will be required.

More can be found out about the NSTF and the pioneering science it will be incubating by following this link: https://www.ralspace.stfc.ac.uk/Pages/National-Satellite-Test-Facility.aspx

The design phase included:

- Development of a Piping and Instrumentation Diagram (P&ID) for the complete system

- Calculations to demonstrate compliance to requirements such as heat load and pressure drop

- HAZOP analysis

- Developing installation instructions

- Budgeting installation costs and programme

- Coordination and planning around the existing building design

- Identifying all interfaces and building infrastructure requirements to support the system

- Non-branded design information to a level of detail to allow construction procurement

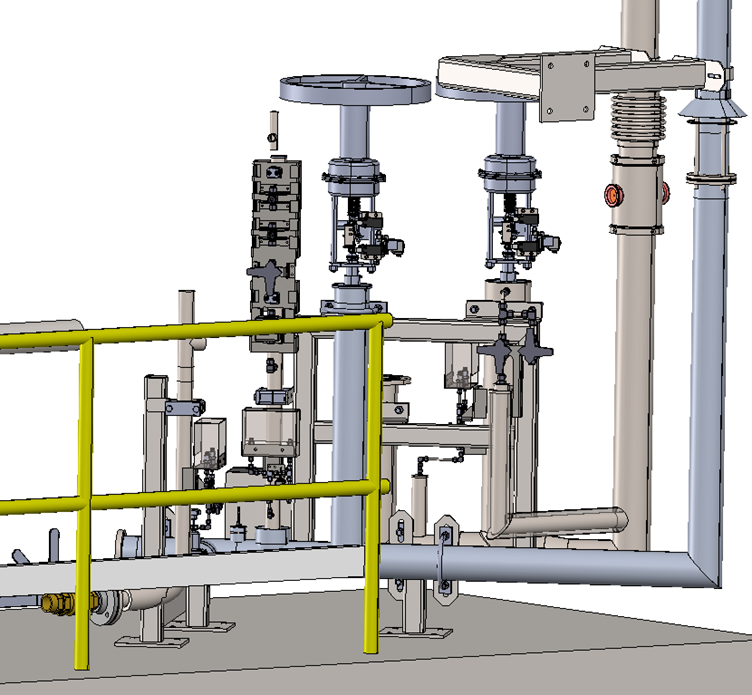

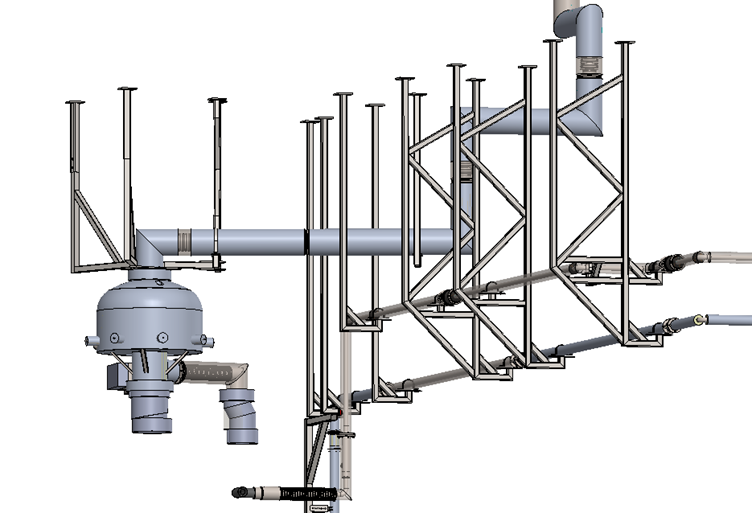

A few images of the design are shown below:

Fieldhouse Engineering Ltd were then contracted to construction partner Mace to build and install Liquid, Gaseous and Exhaust Transfer Lines for the new National Satellite Test Facility (NSTF) in Harwell, Oxfordshire.

The Super Insulated Vacuum Lines (SIVLs) were designed to be modular and easy to install on site. This method has many advantages over the traditional welding approach.

The average heat load, including joints, into the DN50 line is only 0.6W/m and this has been achieved using multiple wraps of Super Insulation and a guaranteed high vacuum cavity.

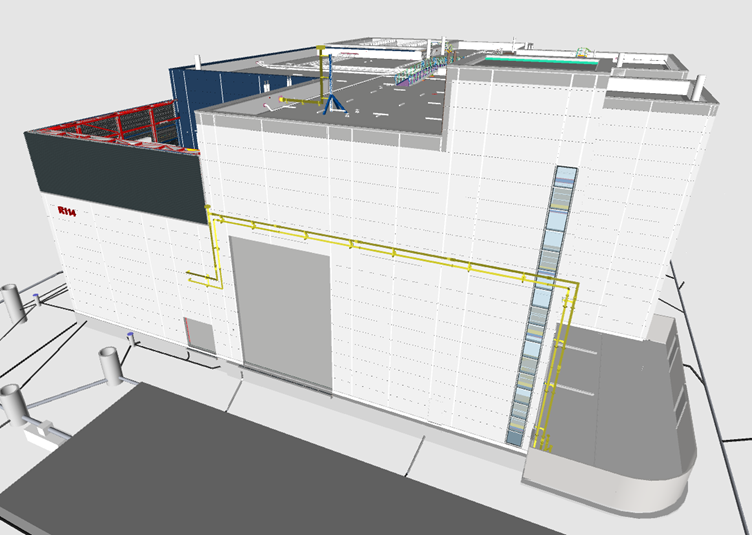

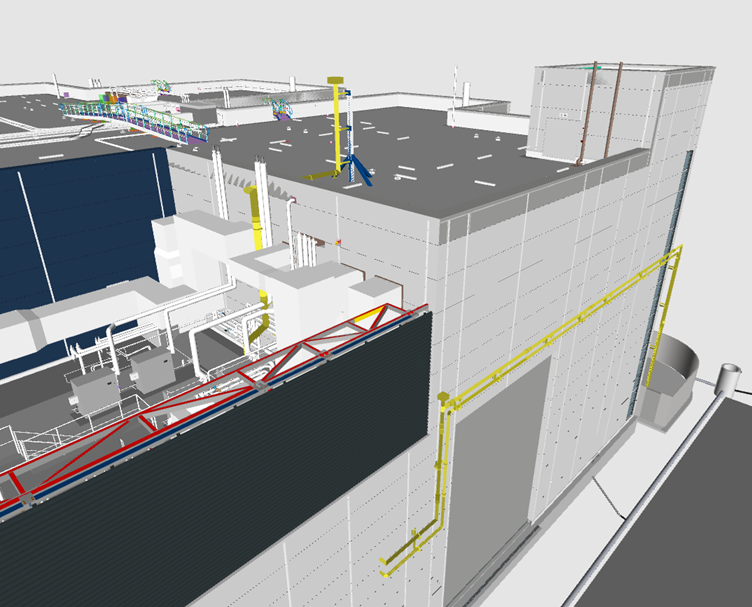

The cryogenic liquid and warm gaseous lines have been designed to connect onto the Liquid Nitrogen Storage Vessels which are located outside the facility. They run up and along the external cladding of the building and then inside the facility, where they connect onto the large satellite testing chamber.

The nitrogen exhaust line then transports the nitrogen to a safe venting location on the roof of the building.

Some images of the site after install are shown below:

If you require a similar service, please don’t hesitate to get in touch.