Designing the Liquid Nitrogen Transfer Lines into the National Satellite Test Facility

Fieldhouse Engineering Ltd were contracted to construction partner Mace to design all the Liquid, Gaseous and Exhaust Transfer Lines for the new National Satellite Test Facility (NSTF) in Harwell, Oxfordshire.

More can be found out about the NSTF and the pioneering science it will be incubating by following the link below: https://www.ralspace.stfc.ac.uk/Pages/National-Satellite-Test-Facility.aspx

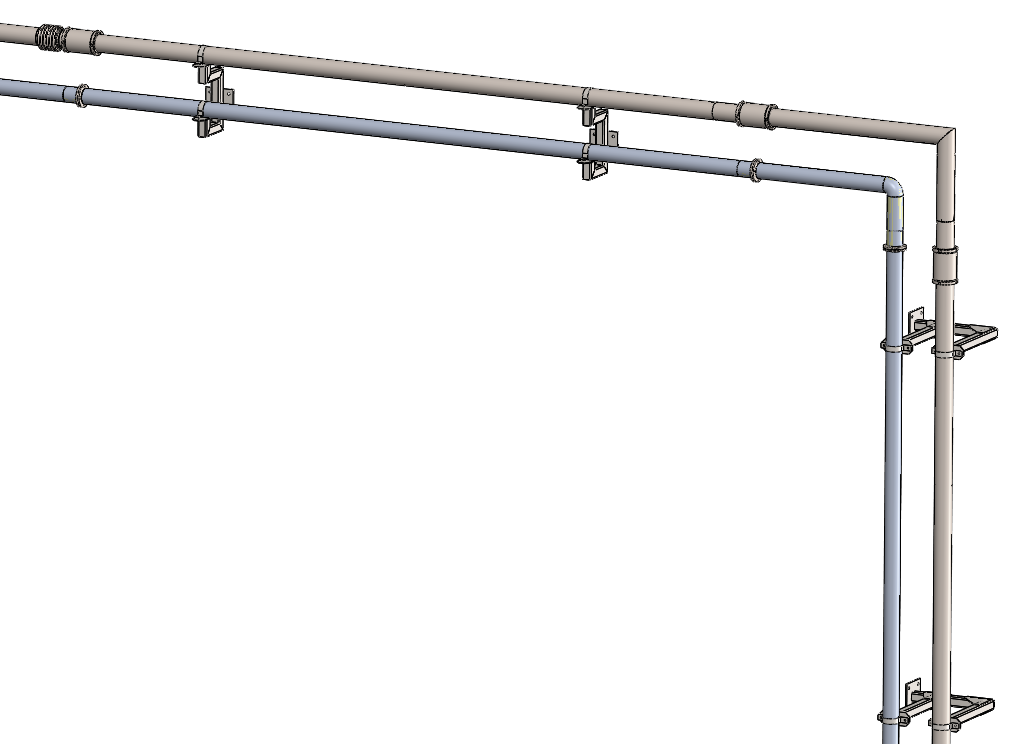

The Super Insulated Vacuum Lines (SIVLs) have been designed to be modular and easy to install on site. This method supersedes the traditional welding approach.

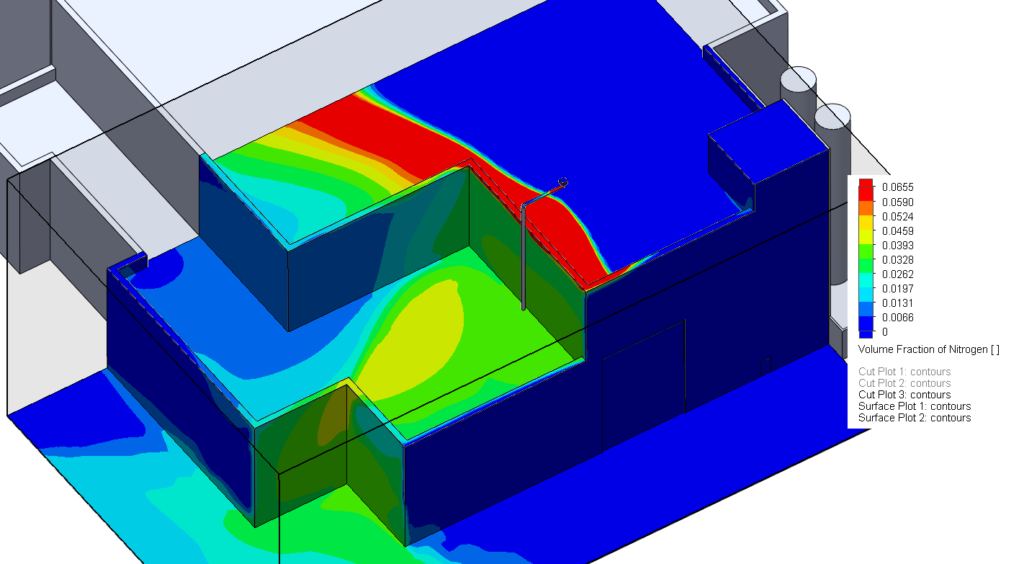

The average heat load, including joints, into the DN50 line is only 0.6W/m and this has been achieved using multiple wraps of Super Insulation and a guaranteed high vacuum cavity.

The cryogenic liquid and warm gaseous lines have been designed to connect onto the Liquid Nitrogen Storage Vessels which are located outside the facility. They run up and along the external cladding of the building and then inside the facility where they connect onto the large satellite testing chamber.

The nitrogen exhaust line then transports the nitrogen to a safe venting location on the roof of the building.

If you require a similar service please don’t hesitate to get in touch.